INTEGRATION OF INDUSTRIAL ROBOTS

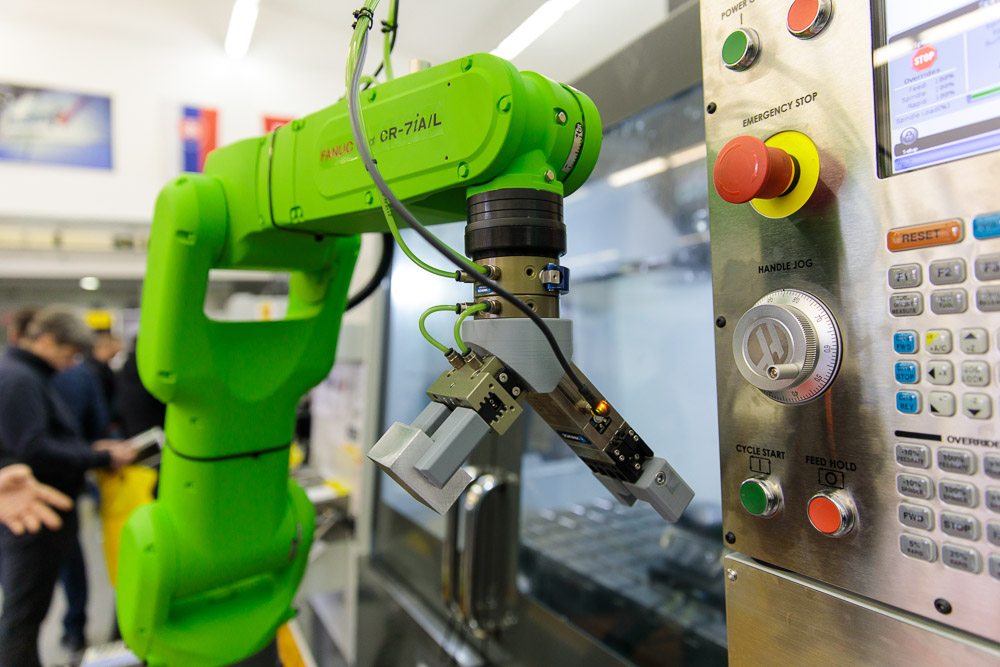

We offer design and implementation of robotic workstations, assembly lines as well as complex automated lines. By integrating workplaces / lines, you will significantly increase OEE, reduce Scrap rates, and ensure traceability of your product portfolio in your company. Industrial robots have been among the standard automation elements for many years and can be used in almost all company processes, from logistics such as palletizing, manufacturing to handling, tightening to quality. Also can be equipped with downstream technology (camera systems, conveyors, etc.) Robotic workplaces can be integrated into existing production lines, if necessary. Especially such a solution significantly reduces your initial investment.

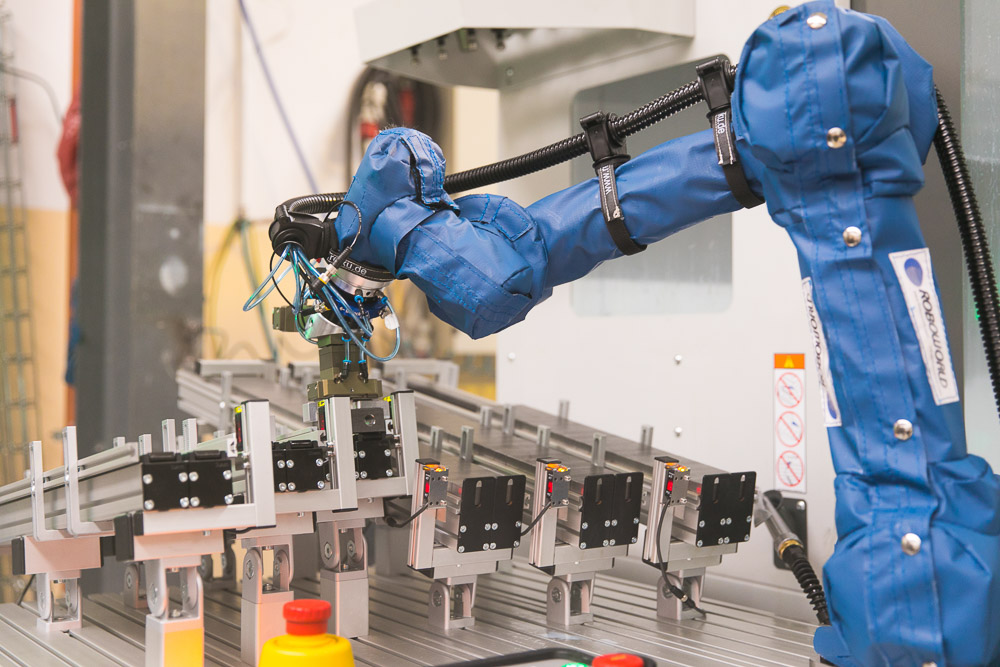

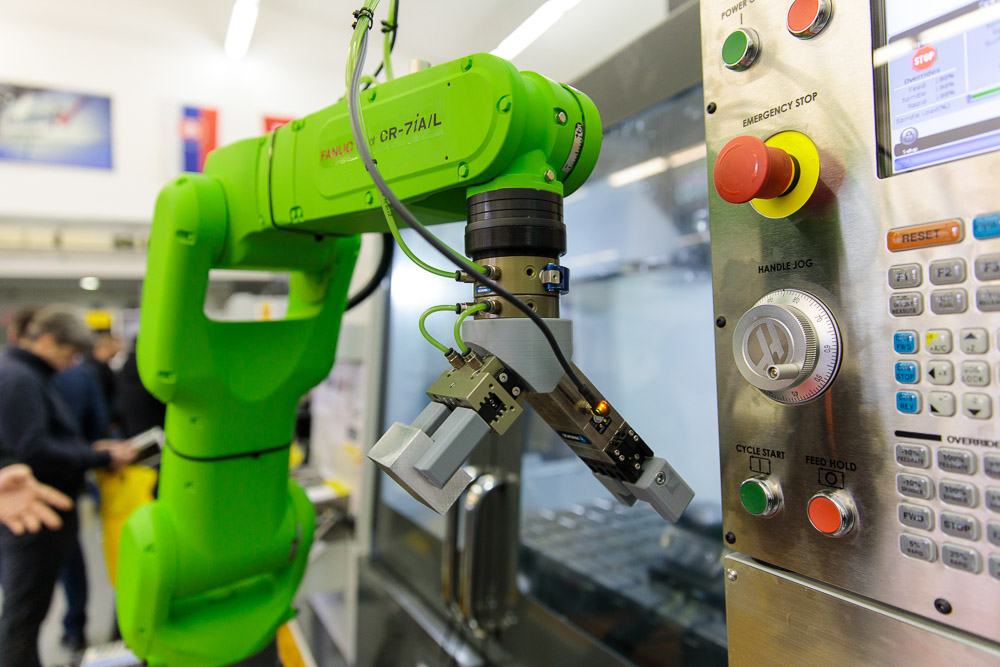

INTEGRATION OF INDUSTRIAL ROBOTS

We offer design and implementation of robotic workstations, assembly lines as well as complex automated lines. By integrating workplaces / lines, you will significantly increase OEE, reduce Scrap rates, and ensure traceability of your product portfolio in your company. Industrial robots have been among the standard automation elements for many years and can be used in almost all company processes, from logistics such as palletizing, manufacturing to handling, tightening to quality. Also can be equipped with downstream technology (camera systems, conveyors, etc.) Robotic workplaces can be integrated into existing production lines, if necessary. Especially such a solution significantly reduces your initial investment.

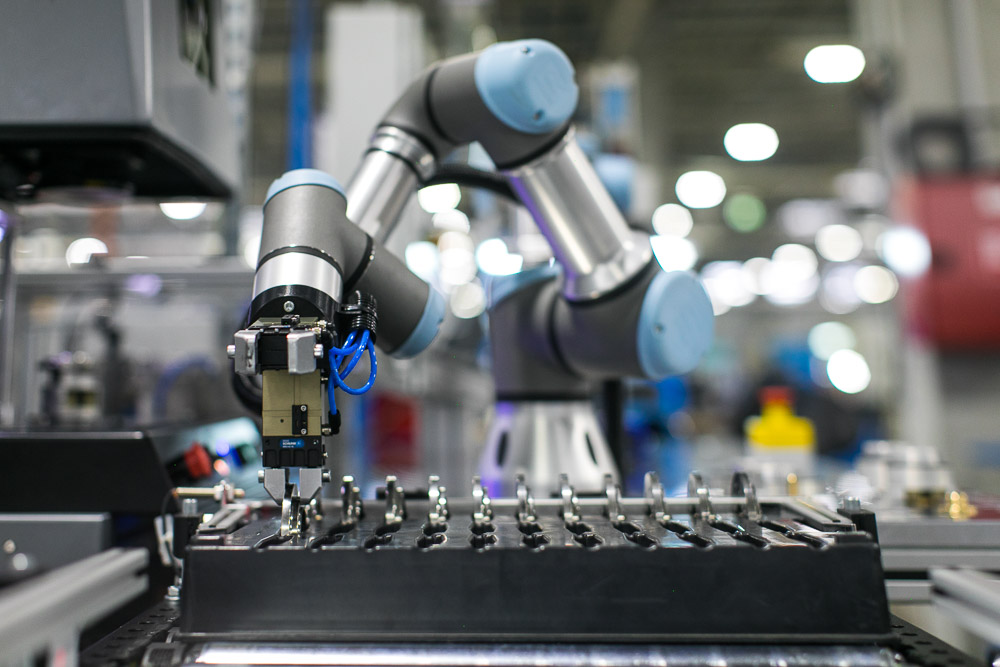

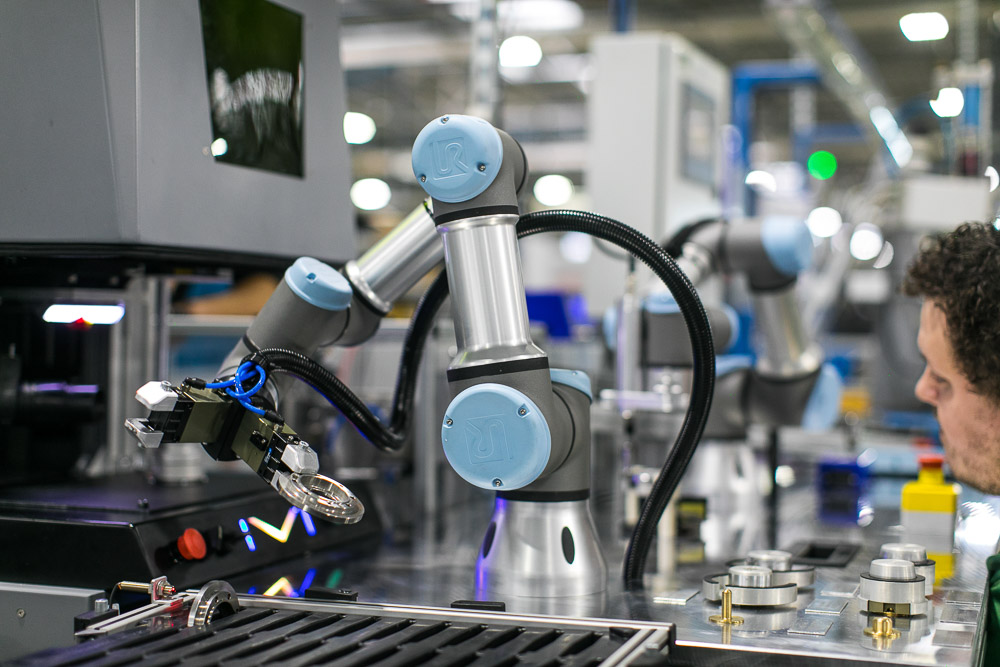

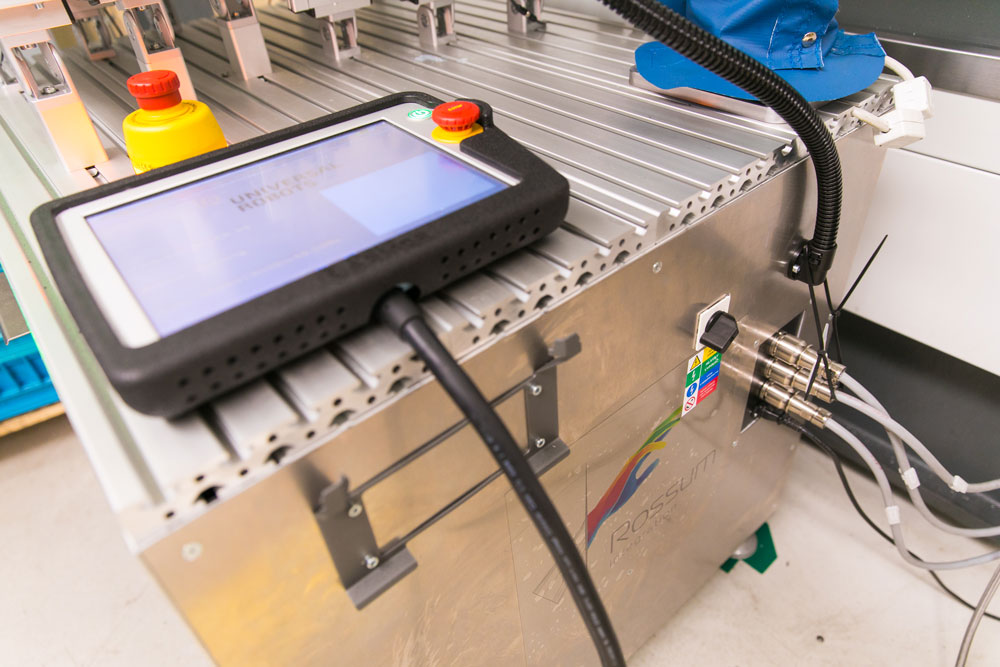

INTEGRATION OF COLABORATIVE ROBOTS

Collaborative robots called “Cobots” begin to be part of manufacturing companies, due to their economical space, security and easy installation. Without additional investments, they can be integrated into existing production lines and thus simply replace the human workforce. The cobots are especially suitable where there is a need to co-operate with a human and robotic arm, we do not require high speeds and we have a limited space to install a robotic workstation. We integrate Cobots with the latest technical specifications such as: ISO / TS 15066. Priority is always human safety in this case.

INTEGRATION OF COLABORATIVE ROBOTS

Collaborative robots called “Cobots” begin to be part of manufacturing companies, due to their economical space, security and easy installation. Without additional investments, they can be integrated into existing production lines and thus simply replace the human workforce. The cobots are especially suitable where there is a need to co-operate with a human and robotic arm, we do not require high speeds and we have a limited space to install a robotic workstation. We integrate Cobots with the latest technical specifications such as: ISO / TS 15066. Priority is always human safety in this case.

SERVICE AND TRAINING

All our facilities are subject to 24/7 service to ensure smooth operation. We train a person to be familiar with the shipment. That person is always responsible when handing the device. If required, we can provide training for different types of control systems and robots. In the case of a machine or equipment failure after the warranty period, a quotation is always drawn based on the severity and duration of the work.

SERVICE AND TRAINING

All our facilities are subject to 24/7 service to ensure smooth operation. We train a person to be familiar with the shipment. That person is always responsible when handing the device. If required, we can provide training for different types of control systems and robots. In the case of a machine or equipment failure after the warranty period, a quotation is always drawn based on the severity and duration of the work.

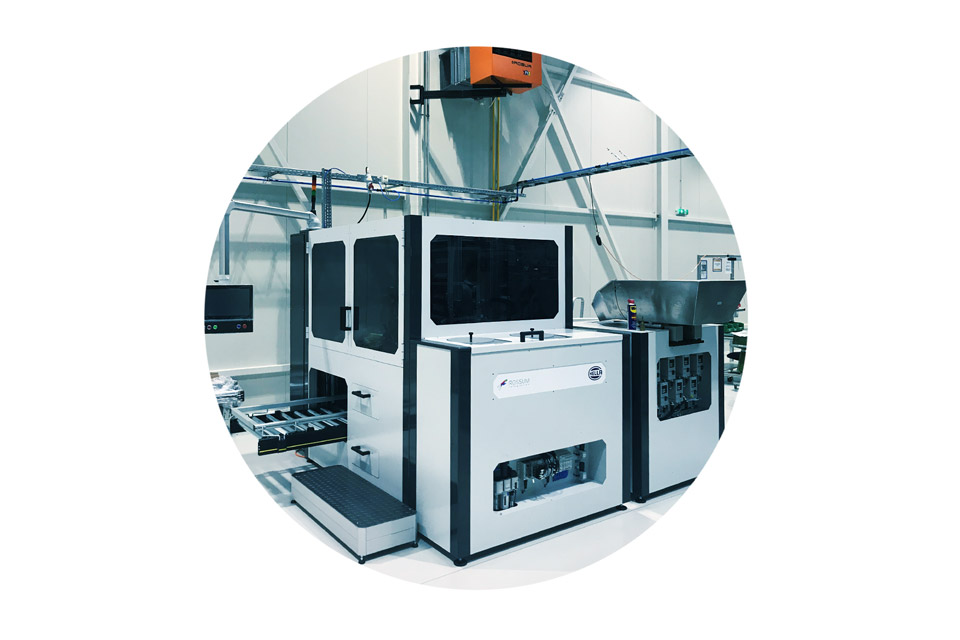

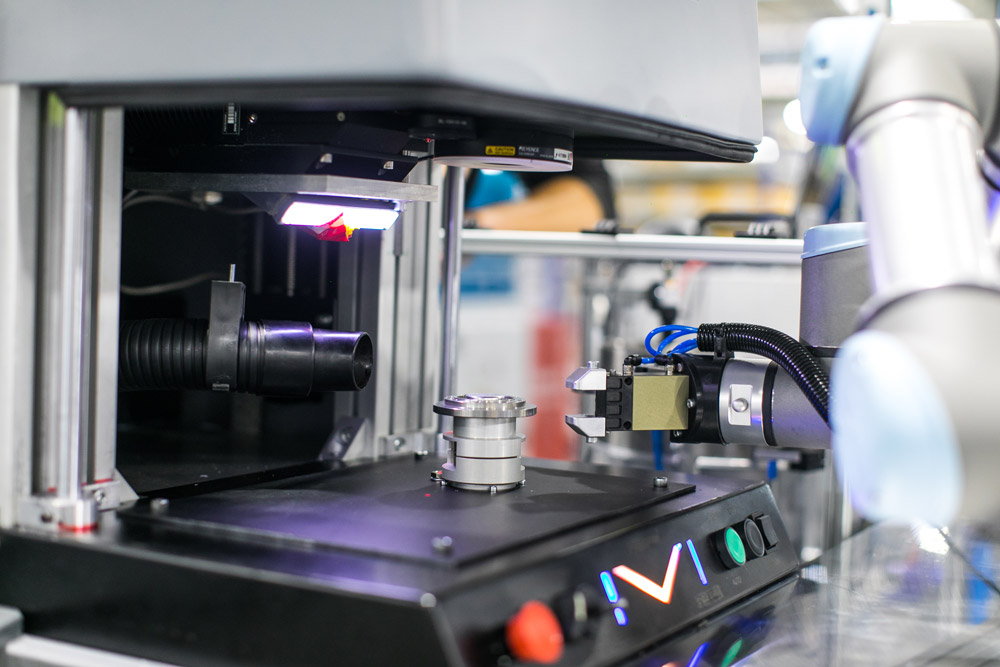

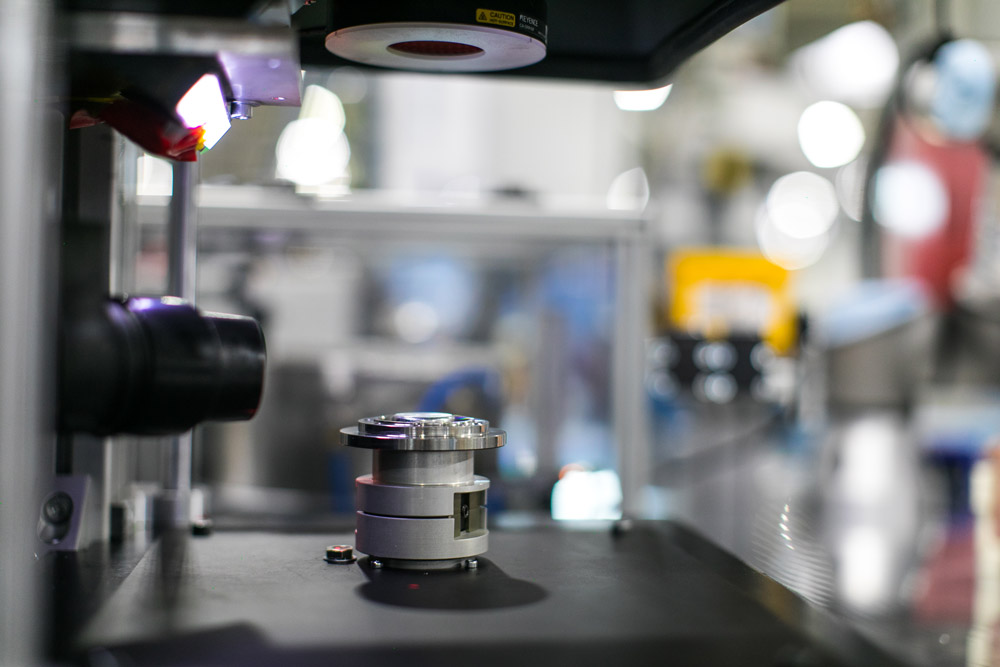

MEASURING AND TESTING STATIONS

These days is highlighted precision and final testing of manufactured product. We are able to produce specialized measuring and testing stations according to customer requirements. Testers are also able to detect the minimum deviation of the measured values with maximum precision and repeatability. The test results are stored in a database, datasheets, graphs and can be used to analyze the process and optimize it.

MEASURING AND TESTING STATIONS

These days is highlighted precision and final testing of manufactured product. We are able to produce specialized measuring and testing stations according to customer requirements. Testers are also able to detect the minimum deviation of the measured values with maximum precision and repeatability. The test results are stored in a database, datasheets, graphs and can be used to analyze the process and optimize it.

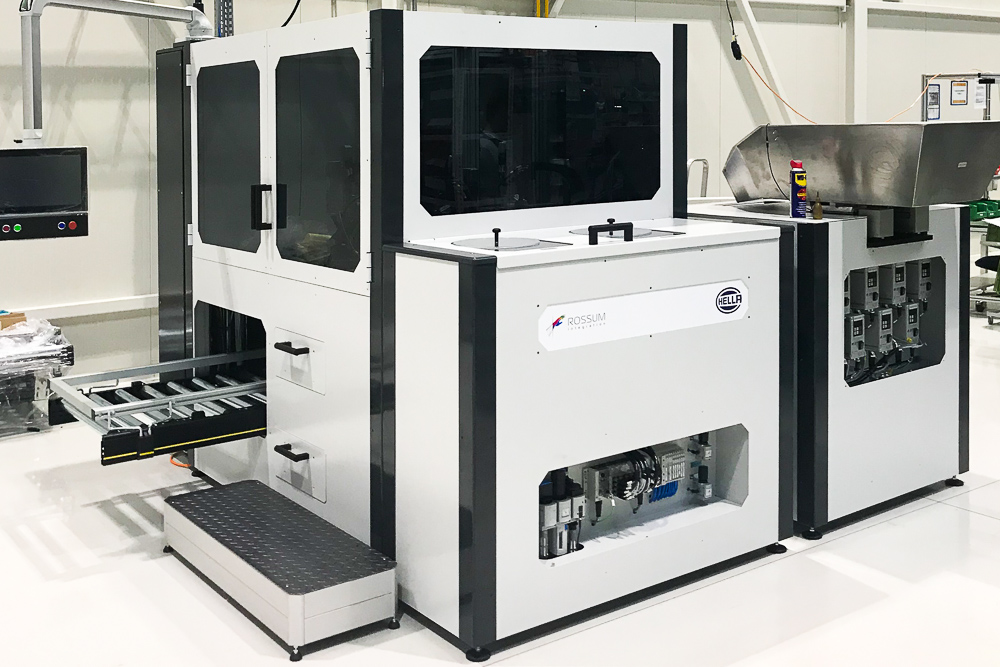

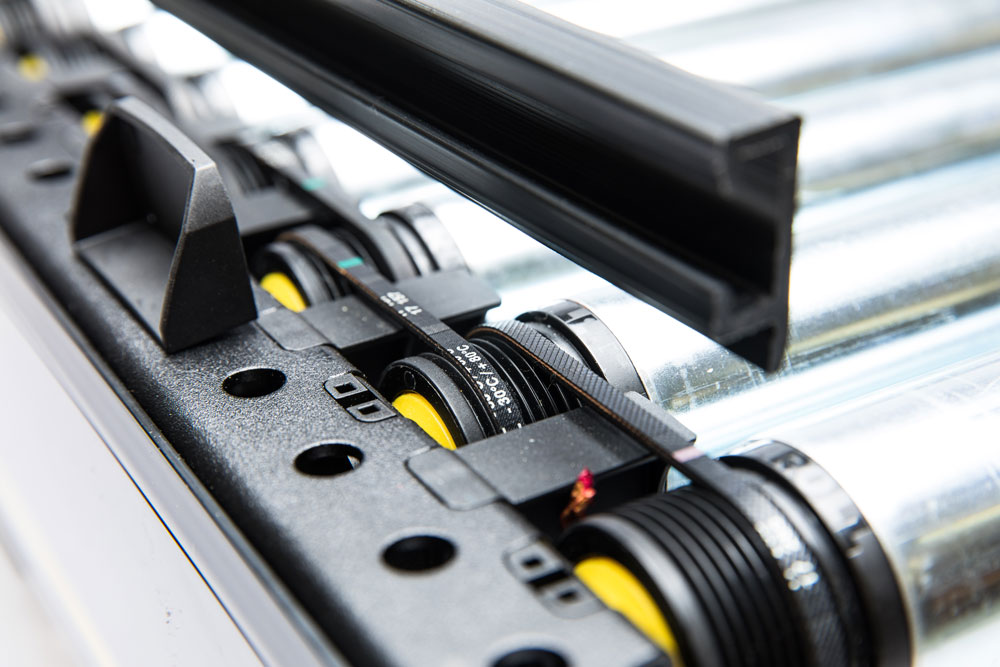

SINGLE-PURPOSE EQUIPMENT

Single-purpose devices are unique, precisely tailored to customer requirements and manufacturing conditions. The design and production of single-purpose machines and equipment is largely influenced by requirements related to applications delivered through automated lines and workplaces. These are mostly devices which are performing a specific type of manipulation or other undefined type of operation. Single-purpose machines and devices that are developed, designed and manufactured by Rossum integrate are used in various automated factories. The technical solution is designed based on specific requirements. The specific device meets required performance, utility and quality criteria.

SINGLE-PURPOSE EQUIPMENT

Single-purpose devices are unique, precisely tailored to customer requirements and manufacturing conditions. The design and production of single-purpose machines and equipment is largely influenced by requirements related to applications delivered through automated lines and workplaces. These are mostly devices which are performing a specific type of manipulation or other undefined type of operation. Single-purpose machines and devices that are developed, designed and manufactured by Rossum integrate are used in various automated factories. The technical solution is designed based on specific requirements. The specific device meets required performance, utility and quality criteria.

AUTO-MANAGED VEHICLES AGV

By integrating AGV autonomously controlled vehicles, we can significantly improve your internal logistics, reduce the risk of downtime in production. Autonomous vehicles are usable in almost every part of your production in the factory, from storage, through production to shipping. With modular solutions, we can create a device directly for your needs and set up a management process to work autonomously.

AUTO-MANAGED VEHICLES AGV

By integrating AGV autonomously controlled vehicles, we can significantly improve your internal logistics, reduce the risk of downtime in production. Autonomous vehicles are usable in almost every part of your production in the factory, from storage, through production to shipping. With modular solutions, we can create a device directly for your needs and set up a management process to work autonomously.